AEC Design is a high technology company that focuses on the design and manufacturing of the crystal based frequency control devices. We have over 30 years of experience in the field of SAW and Microwave devices. Our components are intended for use in Aerospace and Commercial RF markets.

We offer a broad range of RF SAW Filters, SAW Resonators, SAW Delay Lines, Microwave Filters, FBAR and other RF devices for secure communications and navigation.

Initially, AEC Design manufactured devices in the frequency range of 20MHz to 35GHz. AEC Design's SAW Filters, Resonators, Delay lines, Sensors are available for any frequency from 5Hz to 5GHz.

Market Position

We design, prototype and manufacture radio frequency components for Commercial electronic manufacturing industry.Applications and End-User Industries:

- Communications and Mobile Infrastructure

- Instrumentation and Timing Devices

Product range

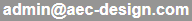

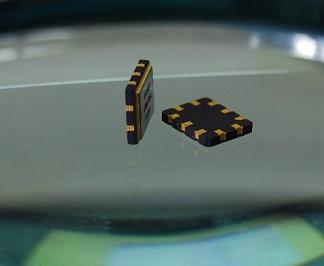

- SAW Filters, SAW Resonators, SAW Delay lines, SAW Sensors, Duplexers up to 5 GHz

- Space qualified Microstrip Filters up to 35 GHz

AEC Design has more then 1250 device part numbers in the product list.

History

- 1979 - Researchers at the specialized department

- 1991 - Foundation of facility in Saint-Petersburg

- 1999 - International sales

- 2008 - Start with the manufacturing of certified RF components

- ISO 9001-2008 certification

- 2010 - The beginning of the design, development and manufacturing of Microwave filters

Factories and Equipment

We have successfully established fully owed production facility in Russia. Our factory have the modern process equipment, including steppers that cover 0.25 micron design rules. By performing design, manufacturing and testing processes in-house, we are able to shorten the lead time and reduce cost. We take an advantage of the possibility to provide the manufacturing cycle in whole: from design to final device in either quantities, down to one unit.

Research and Development

AEC Design develops SAW radio frequency control devices and related software. Custom-designed program "SAWANA" enables to create accurate model prior to producing the physical prototype and reduces the design cycle time.

Technology

AEC Design archives the highest levels of performance using clean room facilities and the latest in technology. In-house mask making, lithography, vacuum and assembling processes are optimized for individual, pilot and volume production. The crystals are assembled in ceramic packages hermetically sealed with glass or ceramic covers. Our highly skilled engineers are ready to develop high performance, low aging RF devices to your specifications. We make every effort to meet our customers requirements including size and weight. We produce the lead PB-free and RoHS compliant components.

Quality System and Certificates awarded

AEC Design have been awarded the ISO 9001:2008 certification for Quality Management System. All equipment is calibrated and traceable to the National Institute of Standards "Electron Standard". The components are tested climatically, mechanically and electronically and compliant with highest standards.

Sales

We supply products domestically from AEC Design's Russia-based headquarters.